Spandex Fabric: The Complete Guide to Properties, Types, and Applications

When DuPont introduced spandex in 1959 under the brand name "Lycra," it changed the textile industry. This synthetic fiber quickly became a key ingredient in everything from jeans to athletic wear, improving how our clothes fit and feel.

Spandex is widely used across many apparel categories today, from denim to activewear. From your favorite jeans to workout gear, this fiber has become so common that we often don't realize how much more comfortable our clothes are compared to what people wore decades ago.

What Makes Spandex Special?

Spandex, also known as elastane, is a synthetic fiber that can stretch up to 500–600% of its original length and still bounce back to its starting size. This recovery ability helps your clothes keep their shape through many wears and washes.

Here's what makes spandex different from other stretchy materials:

Great Elasticity: Spandex provides consistent stretch and recovery through thousands of uses, lasting much longer than traditional elastic materials.

Resists Chemicals: Unlike natural rubber, Swimwear typically uses chlorine-resistant constructions — either specially treated spandex or spandex blended with chlorine-resistant nylon/polyester — rather than assuming every spandex is chlorine-proof. It also stands up to oils, lotions, and detergents.

Sun Stable: Spandex doesn't yellow or weaken under sun exposure like other elastic fibers.

Works in Different Temperatures: The fiber performs well from cold winter weather to hot summer days.

Lightweight: Despite its strength, spandex is light and breathable when mixed with other fibers.

Understanding Spandex Content Levels

The amount of spandex in fabric determines how it feels, performs, and what it's best used for:

Light Stretch (2-5% Spandex Content)

Good for everyday comfort without changing how the fabric looks or feels. Your stretch jeans probably have 3-5% spandex - just enough give for comfortable movement while still looking like regular denim. Dress shirts with 2-3% spandex look professional but feel more comfortable all day.

This small amount of stretch makes a big difference. It prevents pulling and bunching, especially around shoulders and back when you're sitting at a desk for hours. The best part? You often don't even notice these garments have spandex because the stretch is so subtle.

Best for: Jeans, dress shirts, casual pants, lightweight blouses, business wear

Medium Stretch (8-15% Spandex Content)

The sweet spot for active wear and casual clothing. Yoga pants usually have 10-12% spandex, giving you good stretch for poses while bouncing back to shape. This range gives you four-way stretch in knitted fabrics - the material stretches both up-down and side-to-side.

Athletic t-shirts in this range move with you during workouts while keeping their shape after washing. When polyester and 12-15% spandex are combined, you get the foundation for most modern sportswear.

Leggings are probably the most popular use of medium-stretch spandex blends. They're comfortable and versatile enough for everything from errands to casual office wear. The trick is getting enough stretch for comfort without making the fabric so thin it becomes see-through when stretched.

Best for: Activewear, leggings, athletic t-shirts, fitted dresses, yoga wear

High Stretch (20%+ Spandex Content)

Used for specialized applications requiring maximum stretch and compression. Competition swimwear often contains 20-25% spandex to provide compression for competitive advantage while staying durable through countless pool sessions.

Medical compression garments may have up to 30% spandex content to create therapeutic pressure levels. At these percentages, spandex becomes the main performance feature of the fabric.

Best for: Performance swimwear, compression wear, shapewear, medical garments, specialized athletic wear

How Spandex Fabrics Are Made

Knitted fabrics work better with spandex because knit structures naturally stretch. This is why most athletic wear uses knitted spandex blends - the knitting process and spandex work together naturally.

Woven fabrics with spandex require more careful planning. The spandex usually runs crosswise to give stretch in one direction. This is how stretch denim maintains its traditional look while adding comfort.

Fiber blends also matter:

• Cotton-spandex: Comfortable and breathable for everyday wear

• Polyester-spandex: Moisture-wicking and durable for athletic use

• Nylon-spandex: Strong and smooth, ideal for swimwear

Spandex fabric making machine

Where You'll Find Spandex

Athletic and Performance Wear

Modern sportswear uses spandex blends to move with your body during exercise while maintaining shape. Professional athletes depend on spandex-enhanced fabrics for competitive advantage - compression shorts reduce muscle fatigue, while stretch panels in running tights prevent chafing.

Swimwear faces particularly tough conditions: pool chemicals, salt water, UV exposure, and constant stretching. Quality swimwear combines spandex with chlorine-resistant polyester or nylon for durability.

Everyday Clothing

Women's jeans commonly contain spandex for flattering fit. The transformation of denim from purely utilitarian to fashion staple happened largely through adding spandex. Men's clothing has followed - dress pants, casual chinos, and even dress shirts now often include spandex for comfort.

Undergarments and Shapewear

Spandex is essential in bras, providing stretch and recovery needed for proper fit and support. Sports bras particularly depend on spandex blends for compression and support during physical activity.

Shapewear uses the highest spandex content - sometimes 25-40% - to create significant body-shaping effects while remaining comfortable for extended wear.

Medical Applications

Compression stockings for treating circulation problems need specific pressure levels that get lighter from ankle to knee. The spandex content and knitting must work together to provide health benefits consistently.

Post-surgical compression garments support healing while preventing complications, requiring fabrics that maintain consistent compression through washing and extended use.

Environmental Considerations and Sustainable Options

As environmental awareness grows, the textile industry is developing more sustainable spandex alternatives and production methods:

Eco-Friendly Spandex and Recycled Fabric Innovations

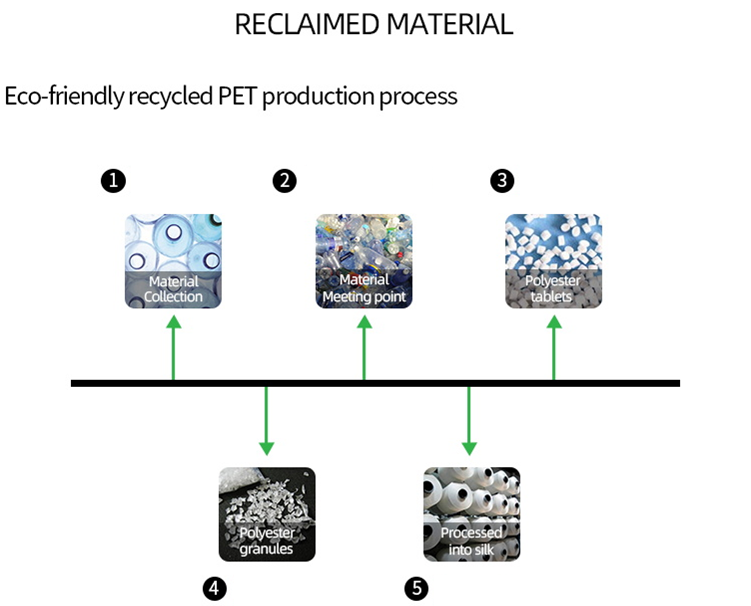

In recent years, the textile industry has made remarkable progress in sustainable fabric development, and spandex blends are no exception. One of the most impactful approaches is the use of recycled polyester (rPET) and recycled nylon, which are derived from post-consumer waste such as discarded plastic bottles, old polyester garments, and abandoned fishing nets. These materials are cleaned, broken down into chips, and spun into high-quality fibers that retain the same durability and elasticity as virgin fibers, but require up to 80% less energy and produce significantly lower carbon emissions.

Advanced recycling technologies now include chemical regeneration, which breaks down old textiles to a molecular level, removes colors and impurities, and recreates fibers that match the strength and feel of new materials. This process has passed rigorous third-party certifications like GRS (Global Recycled Standard) and OEKO-TEX Standard 100, ensuring environmental safety and compliance with strict quality standards — even for infant products.

While recycled fibers may not be biodegradable, they reduce the need for virgin resources, divert waste from landfills, and promote a circular textile economy. For brands and consumers who care about both performance and the planet, eco-friendly spandex fabrics offer a practical, high-performance solution without compromising stretch, comfort, or style.

Bio-Based Alternatives

Emerging bio-based elastane alternatives derived from renewable sources are beginning to enter the market. While still developing, these materials show promise for applications where traditional spandex performance isn't critical.

Sustainable Production Practices

Look for fabrics with certifications like OEKO-TEX Standard 100, which ensures the absence of harmful substances, or Global Recycled Standard (GRS) verification for recycled content claims.

If you’re interested in eco spandex fabrics, see Recycled Fabric suppliers page for details: Recycled Fabric suppliers

Proper Care and Disposal of Spandex Fabrics

Care Instructions for Longevity:

• Wash in cool water (30°C/86°F or less) to prevent fiber degradation

• Avoid fabric softeners which can coat fibers and reduce elasticity

• Air dry when possible as high heat damages spandex fibers

• Store properly away from direct sunlight and excessive heat

Responsible Disposal:

While spandex presents recycling challenges due to its synthetic nature, several options exist:

Textile Recycling Programs: Many communities now accept mixed textiles for processing into insulation, cleaning rags, or other industrial applications.

Brand Take-Back Programs: Some clothing manufacturers offer take-back programs for their products, including spandex-containing garments.

Donation and Reuse: Garments in good condition can be donated or passed along, extending their useful life significantly.

Chemical Recycling: Emerging technologies are developing methods to break down spandex polymers for reformation into new materials, though these are not yet widely available.

How to Choose Quality Spandex Fabrics

When selecting spandex fabrics for your projects, consider these quality indicators:

Performance Characteristics:

• Stretch Recovery: Quality spandex snaps back immediately when released

• Consistent Stretch: The fabric should stretch evenly across its width and length

• Surface Quality: Look for smooth, even surfaces without thin spots or irregularities

• Color Fastness: Premium spandex maintains color stability through washing and wear

Blend Considerations:

The fiber blended with spandex dramatically affects the final fabric's properties:

• Cotton-Spandex: Breathable and comfortable for everyday wear

• Polyester-Spandex: Moisture-wicking and durable for athletic applications

• Nylon-Spandex: Smooth and strong, ideal for swimwear and activewear

• Rayon-Spandex: Soft drape with stretch, perfect for dresses and casual wear

Manufacturing Considerations for Spandex Fabrics

Understanding how spandex fabrics are made helps explain how they perform and guides proper care. The manufacturing process significantly affects the final fabric's properties, durability, and what it's best used for.

Knitted vs. Woven Spandex Constructions

Knitted fabrics generally accommodate spandex more naturally than woven constructions. The inherent stretch of knit structures works synergistically with spandex fibers, creating fabrics with superior comfort and recovery properties. This explains why most athletic wear and activewear uses knitted spandex blends.

Woven spandex fabrics require more careful engineering to achieve optimal performance. Spandex typically runs in the weft direction (crosswise) to provide stretch perpendicular to the fabric's length. This construction creates fabrics like stretch denim that maintain their traditional appearance while offering improved comfort. The challenge lies in balancing stretch properties with the stability expected from woven fabrics.

Fiber Blend Considerations

The choice of fibers blended with spandex dramatically affects the final fabric's characteristics. Cotton-spandex blends prioritize comfort and breathability, making them ideal for everyday wear. The natural properties of cotton complement spandex's synthetic performance, creating fabrics that feel familiar while offering modern benefits.

Polyester-spandex combinations emphasize performance characteristics like moisture management and durability. These blends dominate athletic wear because polyester's moisture-wicking properties combine perfectly with spandex's stretch and recovery. The synthetic nature of both fibers allows for specialized treatments and finishes that enhance performance.

Nylon-spandex blends offer exceptional strength and smooth feel, making them preferred for swimwear and high-performance applications. Nylon's resistance to abrasion and chemicals complements spandex's elasticity, creating fabrics that withstand harsh conditions while maintaining their performance characteristics.

The Future of Spandex

As technology advances and sustainability becomes increasingly important, spandex continues to evolve. New manufacturing processes are reducing environmental impact while maintaining the superior performance characteristics that made spandex indispensable. Bio-based alternatives and improved recycling technologies promise even more sustainable options in the future.

Understanding spandex's properties, applications, and quality indicators enables informed decisions whether you're designing performance athletic wear, comfortable everyday clothing, or specialized technical textiles. The key is matching the right spandex content and blend to your specific application requirements.

From its revolutionary introduction in 1959 to today's advanced formulations, spandex remains one of textiles' most versatile and valuable innovations. Its unique combination of stretch, recovery, and durability continues to enable new possibilities in fashion, athletics, and technical applications.